Samsung’s next-gen chip technology delayed until 2022

Eleanore Beatty October 11, 2021 Article

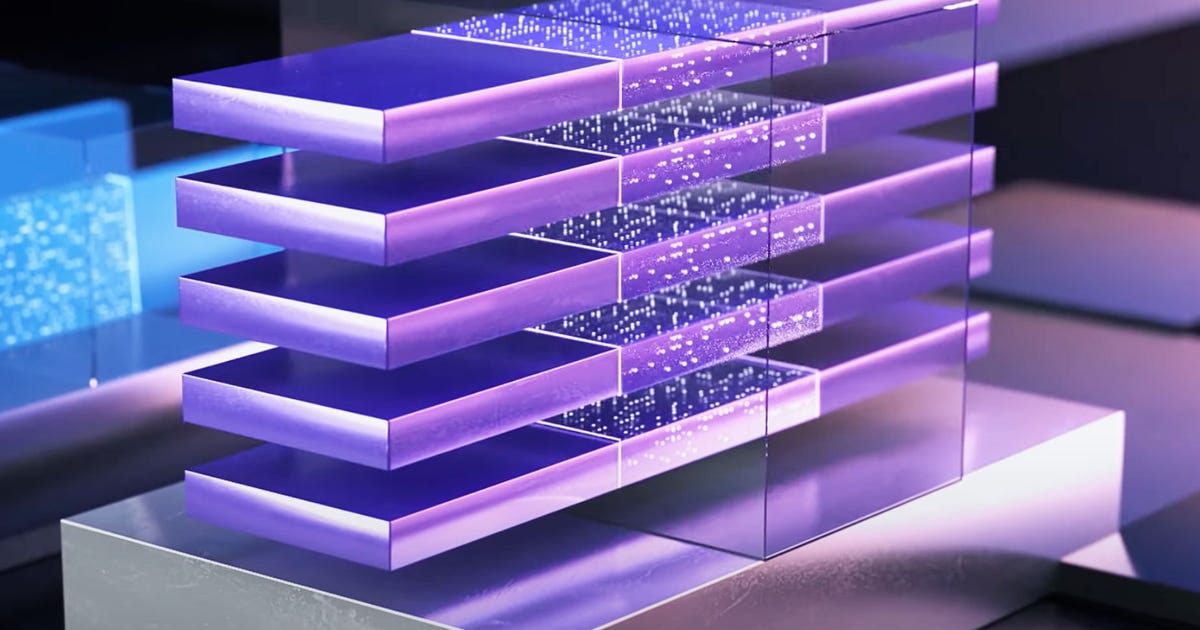

Samsung’s gate-all-all-around transistor design, in which proven right here with purple conductors penetrating a transparent encompassing gate material, is owing to get there in processors in 2022.

Samsung Screenshot by Stephen Shankland/CNET

Samsung, a single of the 3 major edge processor producers, experienced planned to start off making a faster and far more successful class of chips in 2021, but instead the new design and style will in its place get there in the 1st 50 {a78e43caf781a4748142ac77894e52b42fd2247cba0219deedaee5032d61bfc9} of 2022. The Korean electronics giant shared the timetable for the shift all through its Samsung Foundry Discussion board on Wednesday, Home Decor Ideas.

The slip means buyers that depend on Samsung will have to hold out lengthier to faucet into the foremost-edge technology. Amid the biggest names making use of the firm’s providers are mobile phone chip designer Qualcomm, server maker IBM and Samsung itself.

Get the CNET Cellular e-newsletter

Obtain the greatest phones, applications and equipment with our CNET Cell e-newsletter. Shipped Tuesdays and Thursdays.

The excellent information for people customers, while, is that Samsung also declared development in the upcoming generation of producing afterward, a refinement that should get there in the 2nd 50 {a78e43caf781a4748142ac77894e52b42fd2247cba0219deedaee5032d61bfc9} of 2025. That should provide an additional phase forward in chip performance, ability effectiveness and electronics miniaturization, Samsung stated.

Samsung’s major chipmaking rival, Taiwan Semiconductor Production Co., disclosed a delay to very similar technologies in August. The routine slips ease the stress a minor on Intel, which is launching its possess foundry enterprise as part of a recovery strategy aimed at reclaiming the management it lost to TSMC and Samsung.

The processor business is under extreme force. With the pandemic boosting Computer gross sales, smartphone utilization, and on-line products and services operate out of details centers, desire for processors has outstripped production potential. The chip scarcity has hobbled profits of PCs, sport consoles, automobiles and other items reliant on earth-spanning electronics supply chains.

Based mostly on Samsung’s discussions with clients, the processor lack will not likely ease until finally 2022, reported Shawn Han, a Samsung Foundry company senior vice president, centered on Samsung’s discussions with buyers. “From our watch, it will be long lasting yet another six to nine months, whilst we are investing, and other foundries suppliers are increasing their capacity,” he claimed in a briefing in advance of the Samsung Foundry Discussion board.

Transferring to following-era producing technological know-how is terribly sophisticated. Chips are created of billions of digital elements termed transistors, every vastly smaller than a speck of dust. Chip fabrication plants, referred to as fabs, etch the circuitry designs on silicon wafers with a process requiring dozens of actions that acquire months.

Development comes by miniaturizing transistors so more can be squeezed onto a chip, escalating their velocity and reducing their ability intake. Samsung’s future-gen system, which it calls 3GAE, employs a procedure referred to as gate all all around (GAA). It really is an early version of the technological innovation.

In 2023, Samsung expects to get to significant production volume with a extra mature edition called 3Gap. The 3 in the title refers to the 3-nanometer measurement that, whilst no more time right linked to the proportions of chip electronics, serves as a label for progress in manufacturing approaches.

2 nanometer manufacturing in 2025

Then in 2025, the company strategies to transfer to a second, far more highly developed gate-all-all over technologies it phone calls 2Hole. That producing approach will be the 1st of Samsung’s 2nm generation. A person improvement will be in the range of current carrying “nanoribbons” that will penetrate the encompassing gate substance, which will raise from 3 in the 3nm technology to 4 nanoribbons.

As chips get more complex, they also frequently get a lot more costly, which is why many chip customers are sticking with older, less expensive producing processes from companies like GlobalFoundries.

But Samsung thinks it can make the new production procedures monetarily alluring to clients.

“Even however GAA is a complicated technology, We will nonetheless try to decrease the value for each transistor,” stated Moonsoo Kang, head of Samsung’s Foundry Method Group. “That development will carry on.”

Chip packaging improvements

For a long time, Moore’s Law has charted how miniaturization has let chip designers pack much more and extra transistors into a provided chip location. But the slowing rate off miniaturization has made other avenues of progress a lot more significant.

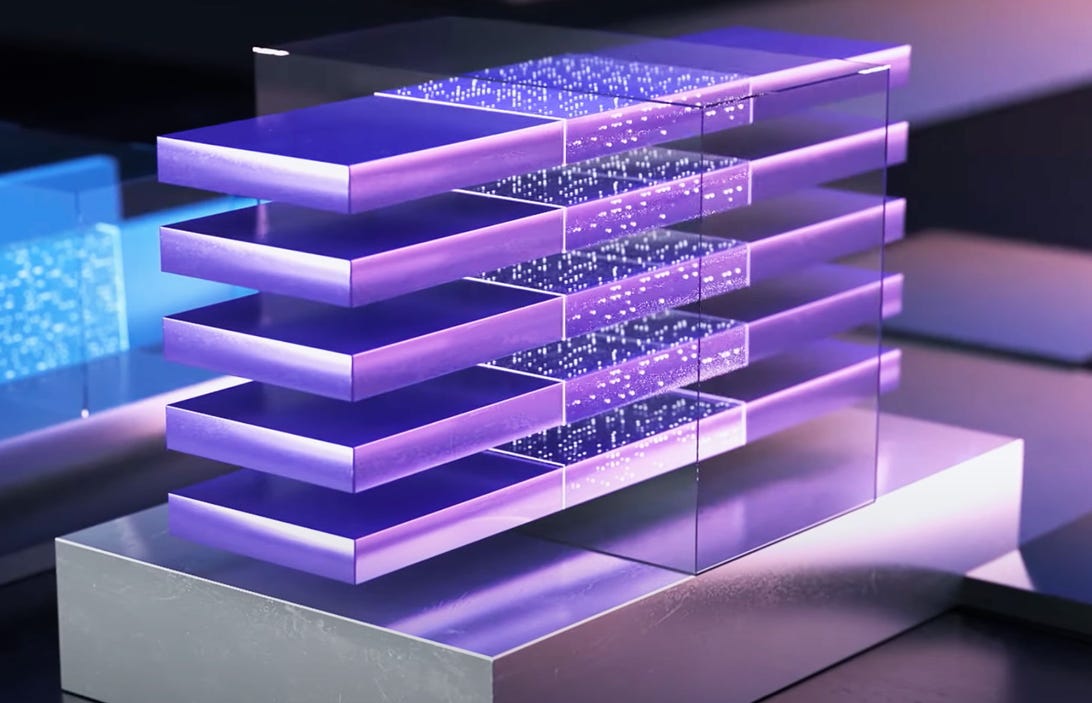

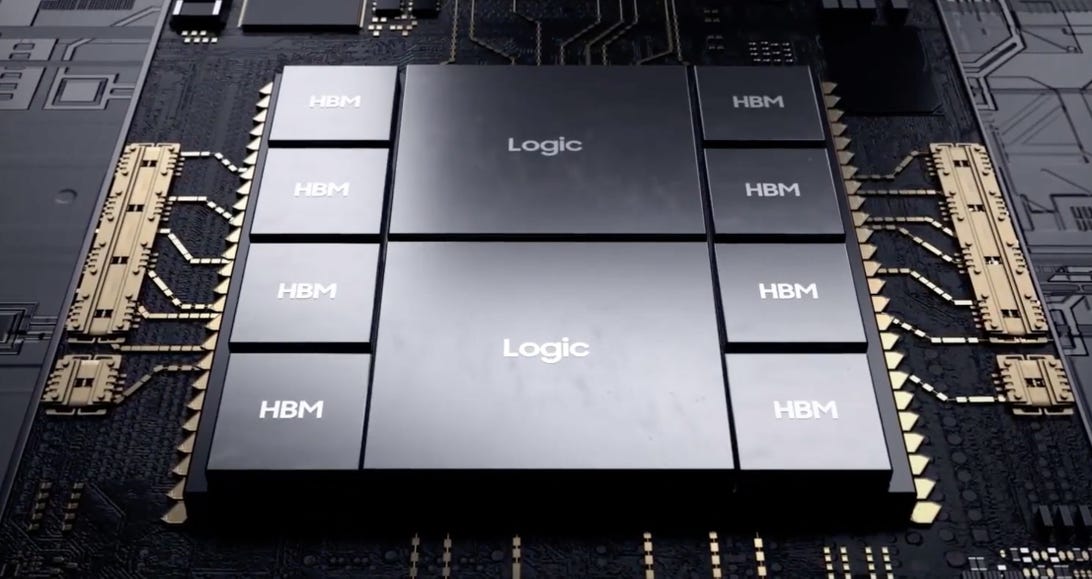

Samsung chip packaging engineering will allow it join eight higher-bandwidth memory chips with two central processors in a long term style named I-Dice8.

Samsung Screenshot by Stephen Shankland/CNET

Just one key way is packaging — the techniques distinct “chiplets” can be connected into a single much larger processor. Samsung is operating to improve the wide range of chips that can be related edge to edge, identified as a 2.5D integrated circuit, or sandwiched on major of eachother, named 3D. It is really also functioning on packing information hyperlinks amongst the chips extra densely for better velocity connections.

And it is really bought a new time period for the combination of 2.5D and 3D connections: 3.5D. “This sort of chip will let us to obtain unprecedented functionality and density,” Kang reported in a talk.

That’s what Intel previously is executing with its Ponte Vecchio processor, an unique chip very good for graphics, synthetic intelligence and supercomputing purposes.

A person major benefit of the packaging developments is an notion termed heterogeneous integration — combining a wide variety of chips crafted with various processes. That allows chipmakers merge costly older manufacturing procedures for some elements and chopping-edge procedures for areas where functionality is critical, for example.

Visit : https://decoideashogar.com/

You may also like

Archives

- December 2024

- November 2024

- September 2024

- August 2024

- July 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

Calendar

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | 31 | |||